Base and precious metals

Our Lean and mining expertise helps integrate two mining projects

132

innovation opportunities uncovered

15

scenarios developed to show project execution at different budgets

Summary

- Two mining companies established a joint venture involving projects located close together, but at different developmental stages. Haley & Aldrich’s Lean and mining experts helped integrate these projects into one viable operation.

- We used Lean practices and team-building exercises to streamline processes and workers’ outlooks. Over a three-day workshop, we developed a project organization chart and confirmed a high-level, commitment-based schedule through feasibility.

- Our clients left the process with 132 innovation opportunities for mining methods, processing and comminution, waste handling, infrastructure, and power — and a comprehensive list of the associated risks.

Client challenge

It was a complicated proposition: After establishing a joint venture of two mining companies with separate projects in geographic proximity but different developmental stages, our client then hoped to integrate them into one viable operation. To succeed, the client had to manage the development and integration of onsite infrastructure and facility design needs that included power, water, access roads, a processing plant, tailings storage, pipelines, and port facilities. It also needed to secure environmental and operational permitting.

Given that one project was in the prefeasibility stage and the other in feasibility, and that the two organizations had differing perspectives, our client was looking at a complicated planning and stage gate process. It was crucial to provide the joint venture’s Steering Committee members with the information — and projected financial numbers — they needed to ease their minds about challenges and green light the entire integration. The client sought out Haley & Aldrich not just for our extensive track record in mining operations, but also for our ability to take on clients’ challenges as our own and provide a path forward that produces the value they need.

Our approach

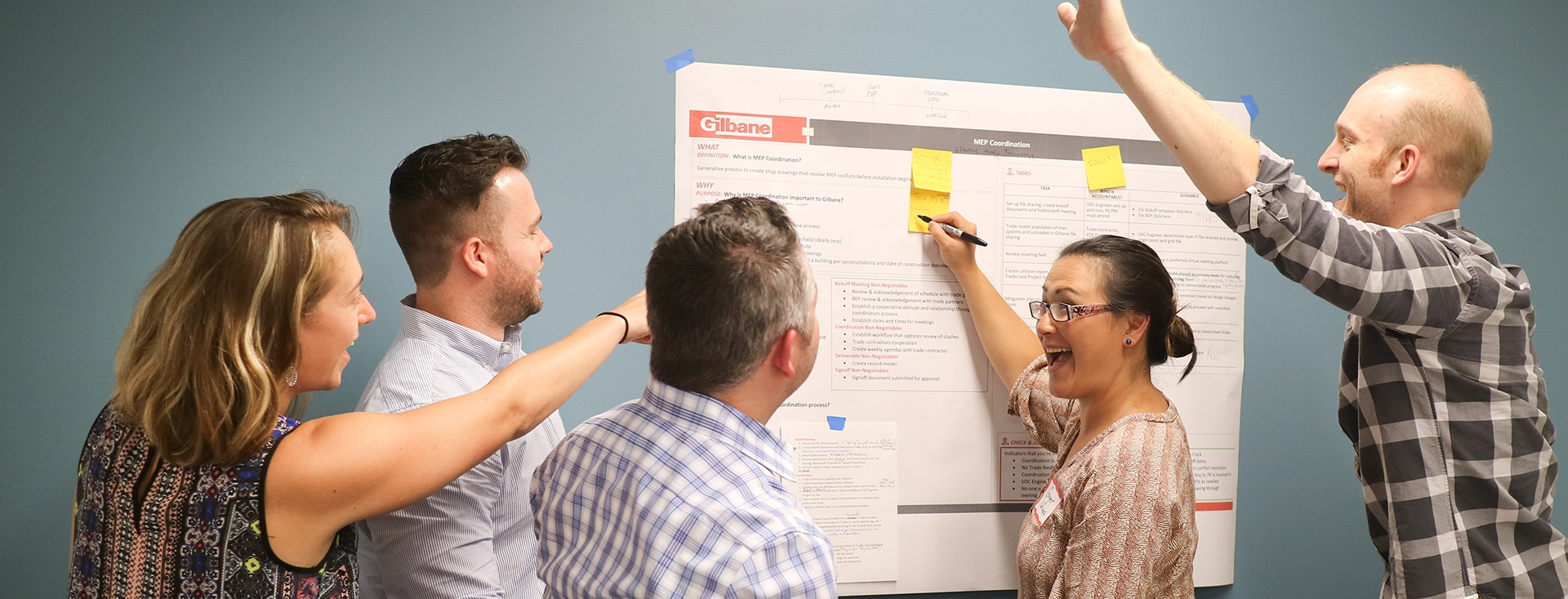

We knew the most effective path was to connect team leaders and their home-office counterparts to cocreate — and therefore align — the combined conceptual and prefeasibility studies. We had to challenge each group’s differing notions about the schedule and process and effectively manage the transition from separate projects to a joint venture to, eventually, one company. Haley & Aldrich used Lean practices and team building exercises to streamline the processes and get everyone on the same page faster and smoother. We developed and facilitated a multiday workshop to consider the known and hidden factors that would make or break this important project.

Instead of weeks of repeated meetings with stakeholders from disparate parties, we quickly broke down the silos and gathered together all necessary participants for three consecutive days. During this workshop, we facilitated conversations and exercises designed to give everyone a voice and ensure everyone agreed upon and understood all crucial aspects of the project.

Using our Lean expertise, we helped our client assess customer value to understand who the customers and key stakeholders were — and learn what was important to identify possible pitfalls and opportunities from the merged operation. We brainstormed and prioritized mine plan scenarios while considering tradeoffs associated with tailings, plant, water, infrastructure, and mining operations. These exercises helped develop a project organization chart and confirm a high-level, commitment-based schedule through prefeasibility. The schedule included gates and milestones that addressed key issues associated with safety, environmental and operational permitting, community relations, and operational constraints — all in just three days.

Value delivered

- Used mining experience and Lean methodology expertise to give our client the organizational structure, roadmap to key data needs, and confirmed schedule needed to get buy-in from the joint venture’s Steering Committee

- Identified 15 different mining operation scenarios to show how the project can be executed at different budgets levels

- Discovered 132 innovation opportunities for mining methods, processing and comminution, waste handling, infrastructure, and power — and identified a comprehensive list of the associated risks

For more information, contact:

Program Manager, Geology